From prototyping to small and large-scale production: STAUFF Technology Centre operates a complete on-site service to assist OEM customers in the Railway Industry (as well as Railway Industry suppliers) in the analysis of existing and the design and development of new hydraulic and pneumatic pipework systems.

STAUFF engineering teams can either work independently throughout the development and prototyping period, or as an integral part of the project design teams and the manufacturing staff to provide the customer with specialist advice and support based on the company‘s experience of being a partner in the European Railway Industry for more than 30 years.

The STAUFF on-site service usually includes a cost-benefit analysis of various options to identify substantial saving potentials by reducing the customer‘s purchasing efforts,

assembly times and material inventories.

Tube Reverse Engineering and Scanning

- Hexagon Absolute Arm

- VTube Laser software

Computerised Bending - High Production

- UNISON BREEZE 50

- UNISON BREEZE 35

End Forming - Assembly Machines/Tools/Devices

- STAUFF Form EVO

- STAUFF Press

- JIC/Flat Face 37°/90°

Tube Finishing

- End capping (screw type or heat shrink seal)

- Labelling (pin stamping, decals, engraving)

- Specialised packaging and crating

- Custom kitting, sub-assembling or production boards

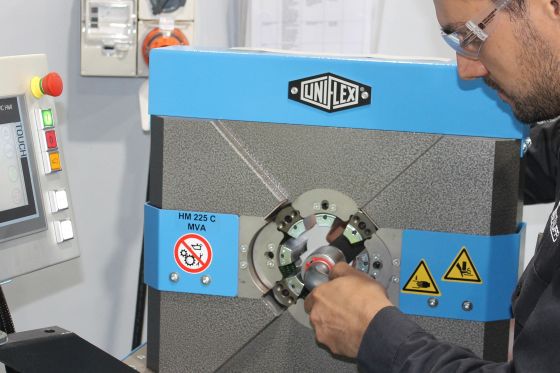

STAUFF Hose Production

- Hose Production

- Hose Accessories

- Hose Testing

Repair and Calibration Services

- Service and Calibration Test Centre

- Pressure Gauge Calibration Services

Engineered Solutions, System Designs, Manufacturing & Fabrication

- Engineered Hydraulic Solutions

- Fluid System Design

- Manufacturing and Light Fabrication