Why correct routing is crucial

Hydraulic systems are the backbone of many industrial applications - powerful, compact and efficient. However, their reliability depends on an often underestimated element: the correct routing of hydraulic hose lines. What may seem trivial at first glance is actually decisive for safety, service life and costs.

Improperly laid hose lines can lead to leaks, loss of performance or even serious accidents. This is precisely why DGUV Rule 113-020 defines clear specifications for the safe use of hydraulic hose lines - regardless of whether they are used in stationary or mobile applications.

What is the DGUV?

The DGUV stands for German Social Accident Insurance. It is the umbrella organisation of the industrial accident insurance institutions and accident insurance funds in Germany. The DGUV coordinates and represents the interests of statutory accident insurance vis-à-vis politics, administration and other institutions. Its aim is to prevent accidents at work, occupational illnesses and work-related health hazards and to ensure effective rehabilitation and compensation in the event of injury.

DGUV Rule 113-020 contains specifications for the safe use of hydraulic hose lines and hydraulic fluids in machines, systems and vehicles. Among other things, it regulates the risk assessment, selection, testing, replacement and storage of these components in order to prevent accidents and health risks.

Risks of improper hose installation

Incorrect routing occurs more frequently than expected - and it has consequences:

Kinks or excessively tight bending radii put a strain on the hose line and shorten its service life.

Torsion and twisting can occur during installation and lead to leaks later on.

Contact with sharp edges or hot surfaces will damage the hose cover.

There is no room for manoeuvre - for example with working cylinders or swivel arms - which results in tensile stress.

Overall, this increases the risk of pressure loss, hose bursts and personal injury - an unnecessary safety risk that can be avoided with good planning.

What DGUV Rule 113-020 specifies

DGUV Rule 113-020 "Hydraulic hose lines and hydraulic fluids" specifies how hose lines must be installed, operated and maintained in order to minimise health and safety risks. The employer is personally liable for compliance with this rule.

Some key points:

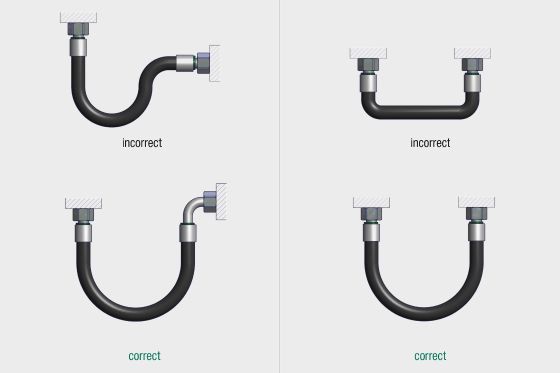

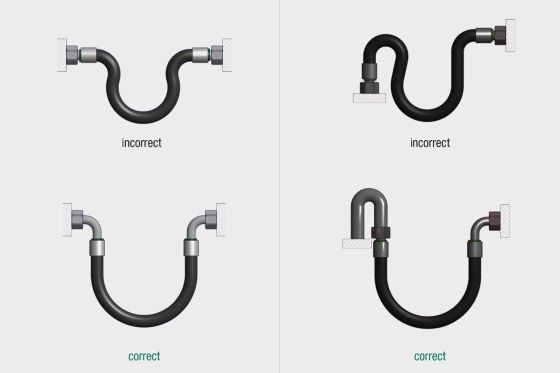

Minimum bending radii must be observed

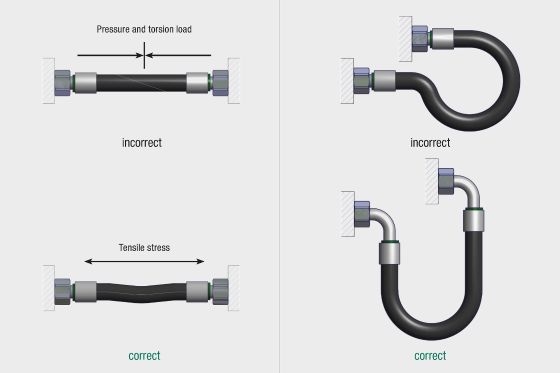

Installation without torsion or buckling load

Mechanical protection against external influences

Secure fastening with suitable holders

Labelling and documentation of the hose lines

Regular inspection and timely replacement

These requirements apply equally to stationary and mobile systems - i.e. also on construction sites, in agricultural engineering or when used on vehicles.

Laying hydraulic hose lines correctly - you should pay attention to this

Hydraulic hose lines must be installed carefully and in compliance with certain guidelines in order to ensure safe and reliable operation. To give you a simple overview, we have summarised a few basic points that you should pay attention to:

- Choose the right length

The hydraulic hose line must be long enough to avoid kinks and tensile loads during operation. - Observe the bending radius

The minimum bending radius specified by the hose manufacturer must not be undercut, as otherwise the service life of the hose lines may be reduced. - Ensure torsion-free installation

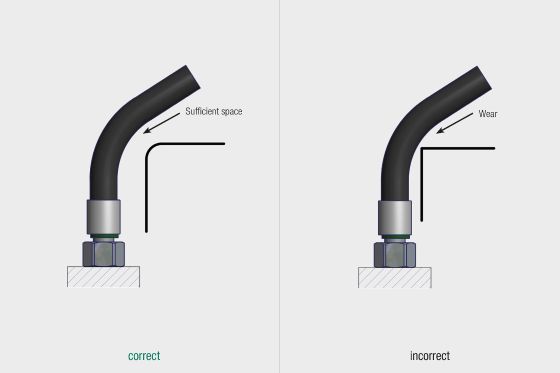

During installation, ensure that the hose line is not twisted. - Avoid chafing

The hose line should be laid as freely as possible so that there is no abrasion of the upper hose cover. If you cannot guarantee a freely laid hose line, a chafe guard can be fitted. - Use secure fastening

Hose clamps - from STAUFF, for example - ensure secure guidance, prevent uncontrolled movements and undesirable stress caused by the hose line's own weight.

STAUFF hose line solutions in practice

With our wide range of hydraulic hoses, fittings and system components, we offer solutions that not only meet the technical requirements, but also help to implement the DGUV specifications in compliance with regulations.

Examples from practice:

STAUFF hoses and fittings are designed for high pressures and tight bending radii and are certified accordingly.

STAUFF hose clamps reliably secure hose lines against movement and vibration.

We will be happy to assist you in selecting and designing the right components for your application.

Please note

The comprehensive stocking of STAUFF tubing and pre-assembled tubing lines is currently limited to selected STAUFF companies and partners. Do you need comprehensive hose line solutions? Please contact us at any time.

FAQs

When do hydraulic hose lines need to be replaced?

Can anyone install hydraulic hose lines?

No. According to the DGUV and the Ordinance on Industrial Safety and Health, only authorised persons with the appropriate qualifications and knowledge of the regulations may install and repair hose lines.

What happens if hose lines are installed incorrectly?

In addition to failures and pressure losses, serious injuries can be caused by escaping fluids - especially with high pressures or hot media.

Newsletter registration

Register now and don't miss any new articles!