Why this topic is important

Hydraulic systems must work safely, reliably and efficiently. However, the screw connections are often not considered at the planning stage. This results in emergency solutions that can lead to leaks, higher maintenance costs and reduced performance during operation.

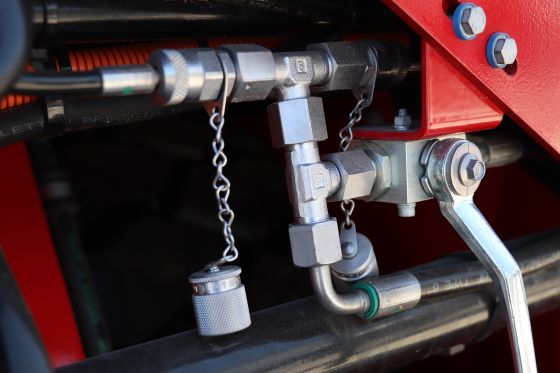

A common example is "stacking", i.e. the stacking and lining up of fittings and adaptors: instead of a suitable, properly planned connection, several standard adaptors are installed one after the other to bridge different connection sizes. What seems "simple" or "available" in the short term leads to avoidable problems in the long term.

At STAUFF, we know that: Those who think ahead here save time, costs and hassle - and provide the customer with a really well thought-out, high-quality solution.

What does stacking mean?

Stacking refers to the practice of screwing together several standard adapters or fittings one after the other in order to connect different connection sizes. A classic example is the transition from a ½" cable to a ⅛" port using three or four stacked adaptors - a design often mocked as a "Christmas tree".

However, stacking does not only occur when overcoming size differences. It also occurs when distances between two connection points have to be bridged with several screw connections or spacers due to inaccurate planning.

In both cases, the result is an unnecessarily complex and potentially error-prone screw connection solution.

Risks and disadvantages of stacking

More leakage paths and inspection points

Every screw connection is a potential leakage path. Multiple stacked connections increase the number of inspection points and the risk of leaks. Added to this is the dependence on error-free assembly: every connection must be correctly sealed and tightened with the correct torque, which significantly increases the assembly effort.

Higher material and assembly costs

Although standard parts often appear inexpensive, the costs for several screw connections and adaptors quickly add up. Assembly time is also increased. This results in higher maintenance and inspection costs over the entire life cycle.

Poorer flow control

Multiple components create avoidable transitions and additional obstacles in the flow path. This can cause turbulence and pressure losses. In the worst-case scenario, a larger pump must be used to compensate for the drop in performance - which incurs further costs.

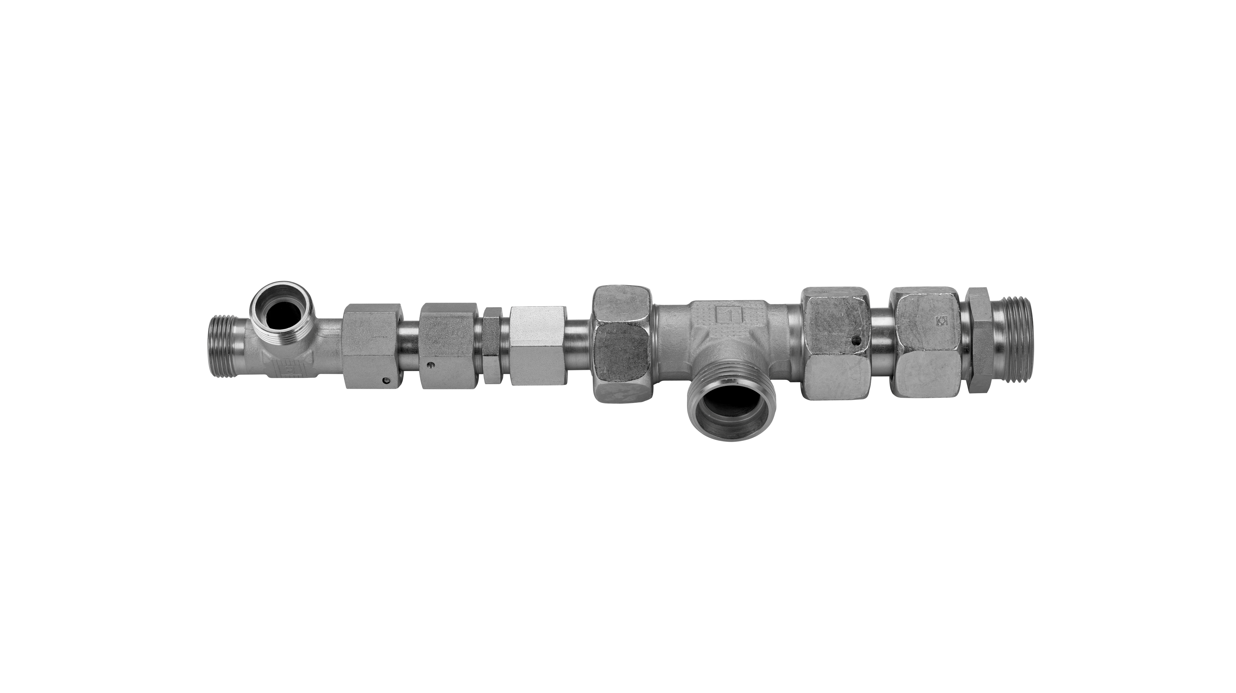

The better solution: Reducing and jump-size unions

The technically clean alternative to stacking is a well thought-out connection solution that is planned from the outset. This includes suitable reducer fittings or so-called jump-size fittings, which can be used to securely connect different connection sizes in a single component.

Equally important: If it is only a matter of bridging a short distance between two connection points, this should not be done with several stacked pipe fittings. A much more elegant solution is available here - for example, by using a customised pipe or hose. This allows the connection to be realised simply, securely and with minimal sealing effort.

Regardless of the specific technical realisation:

Consistent system planning prevents improvisation. At STAUFF, we support our customers in planning efficiently right from the start - with a wide range of products, in-depth technical understanding and many years of experience in the field of connection technology.

If you are planning a project or are already in the implementation phase, we will be happy to advise you on finding the right connection solution - be it through our standard portfolio or through the targeted selection of the best connection and jointing concepts for a specific application.

The goal: connections that are permanently reliable - without unnecessary sealing points, without stacking, without compromises.

Practical tip: Better planning than improvisation

The best way to avoid stacking is to plan ahead.

Take connection sizes into account early on in the design.

Systematically check where jump sizes or reductions are required.

Allow delivery times for special sizes - usually a few weeks, but faster if required.

Take advantage of STAUFF's advice and expertise to specify the right solution for your application.

Careful planning not only ensures a high-quality technical solution, but also saves you money on installation and maintenance.

Conclusion: Jump instead of stack - your key to better solutions

Hydraulic systems rarely fail due to large components, but often due to small details such as incorrectly selected screw connections.

The message is simple: stacking is not a clean engineering solution, but an expensive improvisation. With the right planning and the targeted use of reducer and jump-size fittings, you can avoid unnecessary leakage paths, reduce assembly and inspection costs and sustainably improve the performance of your systems.

STAUFF supports you with a comprehensive portfolio of jump-size fittings and expert technical advice - for a safe, durable and economical hydraulic solution.

FAQs

What is a compression fitting?

Why is stacking done so often anyway?

Because standard parts are readily available and the problem often only becomes apparent at a late stage. In the short term, it seems simple and inexpensive, but in the long term it is often more expensive, more error-prone and therefore less reliable.

Aren't reducing unions more expensive?

Yes, they often cost a little more per unit. But the overall costs are lower because several adaptors and the additional assembly work are eliminated.

However, the majority of step sizes are standard products at STAUFF, so the price difference is usually limited.

What solutions does STAUFF offer?

STAUFF offers a comprehensive range of high-qualityfittings, including reducers and jump-size variants, for securely connecting a wide variety of connection sizes.

Above all, however, we see ourselves as a partner for efficient and well thought-out system planning. Our aim is to help you realise clean, leak-proof and low-maintenance connections right from the start - without the need for stacked improvisations.

If you are planning a project or would like to optimise existing systems, we will be happy to support you with technical advice and a solution-oriented selection of suitable components.

Newsletter registration

Register now and don't miss any new articles!